Eplan Panel P8 2.6 Crack Only

Eplan Panel P8 2.6 Crack Only Average ratng: 3,9/5 6268 reviews

Plus, you can share photos, files, and messages instantly with any Paltalk user. No Webcam is required to see people. 8.3 x 22 inch tractor tires. If you want to chat without the video and voice features, you can always instant message and use Paltalk for real-time text chat.

Mar 11, 2017 - [IMG] EPLAN Electric P8 2.6 (Electric P8, Fluid, PPE, Pro Panel) Win64. Eplan pro panel 2.6 and also eplan electri 2.7 and not able to patch. Has released 2.6 version of EPLAN Platform P8. With the new EPLAN Platform, version 2.6. Users can only update the main. Including the EPLAN Pro Panel. EPLAN Pro Panel v2.6 Build 10395 x64 – Advanced electrical design software. 2.6 the EPLAN Platform can only be run. 2 6; Pro Panel 2 6 3 10395; 0M8H; eplan crack.

Hello 2 allEplan P8 2.7 Torrent

today I have the new EPLAN v2.6 to shareEnjoy

EPLAN ELECTRIC P8 2.6

EPLAN Electric P8 offers unlimited possibilities for project planning, documentation, and management of automation projects.With your choice of graphical or object orientation as well as refined platform technology, this high-end system is breaking new ground in electrical engineering. Its unique functional scope and direct connection to fluid and EMSR technology makes interdisciplinary work a reality.

Data from earlier planning phases can simply be imported using interfaces like ODBC, XML, or Excel – for consistency and perfect integration.

In other words: To shape your future, use EPLAN Electric P8.

EPLAN platform strategy: The modular platform provides core functions that are required in electro-CAE as well as in fluid or instrumentation & control engineering. The advantage of this is consistent data management and uniform processing in all disciplines.

Data from earlier planning phases can simply be imported using interfaces like ODBC, XML, or Excel – for consistency and perfect integration.

In other words: To shape your future, use EPLAN Electric P8.

EPLAN platform strategy: The modular platform provides core functions that are required in electro-CAE as well as in fluid or instrumentation & control engineering. The advantage of this is consistent data management and uniform processing in all disciplines.

Show

EPLAN_Electric_P8_2.6.part01.rar

EPLAN_Electric_P8_2.6.part02.rar

EPLAN_Electric_P8_2.6.part03.rar

EPLAN_Electric_P8_2.6.part04.rar

EPLAN_Electric_P8_2.6.part05.rar

EPLAN_Electric_P8_2.6.part06.rar

EPLAN_Electric_P8_2.6.part07.rar

EPLAN_Electric_P8_2.6.part08.rar

EPLAN_Electric_P8_2.6.part09.rar

EPLAN_Electric_P8_2.6.part10.rar

EPLAN_Electric_P8_2.6.part11.rar

EPLAN_Electric_P8_2.6.part12.rar

EPLAN_Electric_P8_2.6.part13.rar

EPLAN_Electric_P8_2.6.part14.rar

EPLAN_Electric_P8_2.6.part02.rar

EPLAN_Electric_P8_2.6.part03.rar

EPLAN_Electric_P8_2.6.part04.rar

EPLAN_Electric_P8_2.6.part05.rar

EPLAN_Electric_P8_2.6.part06.rar

EPLAN_Electric_P8_2.6.part07.rar

EPLAN_Electric_P8_2.6.part08.rar

EPLAN_Electric_P8_2.6.part09.rar

EPLAN_Electric_P8_2.6.part10.rar

EPLAN_Electric_P8_2.6.part11.rar

EPLAN_Electric_P8_2.6.part12.rar

EPLAN_Electric_P8_2.6.part13.rar

EPLAN_Electric_P8_2.6.part14.rar

EPLAN P8 FLUID 2.6

EPLAN P8 FLUID 2.6EPLAN Fluid supports fluid engineering with automated documentation. Simple handling, numerous test functions, and standard support make your design efficient – from now on the system assumes time-consuming standard tasks.

Compared with conventional, mostly CAD-based systems EPLAN Fluid comes with unique logic functions and automatisms that accelerate your fluid planning. The modern user interface with extensive drawing functions helps you familiarize yourself with its full potential – of course with the complete data stock from the predecessor system fluidPLAN. The autoconnect function applies to all connections that can be provided and analyzed with logical properties. This means you have an overview of all components, including the small parts like connectors, hoses, and pipes – and therefore a firm grip on the costs!

The new Engineering platform is your key to the future, providing core functions for fluid, electrical, measuring, and control engineering as well as CAE for electrica systems. Based on a unified platform all systems are suppliedfrom the same database. From now on multiple data entries and inconsistencies are history.

Besides a unified database the platform also includes basic functions like thegraphical editor (for circuit diagrams, fluid plans, process control group plans), a unified rights management, the viewer, online/offline foreign language transla-tions, and the comprehensive audit system. The unique framework concept deliversimpressively fast results – not least of all owing to the unified look & feel throughout all applications.

Compared with conventional, mostly CAD-based systems EPLAN Fluid comes with unique logic functions and automatisms that accelerate your fluid planning. The modern user interface with extensive drawing functions helps you familiarize yourself with its full potential – of course with the complete data stock from the predecessor system fluidPLAN. The autoconnect function applies to all connections that can be provided and analyzed with logical properties. This means you have an overview of all components, including the small parts like connectors, hoses, and pipes – and therefore a firm grip on the costs!

The new Engineering platform is your key to the future, providing core functions for fluid, electrical, measuring, and control engineering as well as CAE for electrica systems. Based on a unified platform all systems are suppliedfrom the same database. From now on multiple data entries and inconsistencies are history.

Besides a unified database the platform also includes basic functions like thegraphical editor (for circuit diagrams, fluid plans, process control group plans), a unified rights management, the viewer, online/offline foreign language transla-tions, and the comprehensive audit system. The unique framework concept deliversimpressively fast results – not least of all owing to the unified look & feel throughout all applications.

Show

http://adf.ly/1jwhtO

http://adf.ly/1jwhtP

http://adf.ly/1jwhtQ

http://adf.ly/1jwhtR

http://adf.ly/1jwhtS

http://adf.ly/1jwhtT

http://adf.ly/1jwhtU

http://adf.ly/1jwhtV

http://adf.ly/1jwhtW

http://adf.ly/1jwhtX

http://adf.ly/1jwhtY

http://adf.ly/1jwhtZ

http://adf.ly/1jwhta

http://adf.ly/1jwhtP

http://adf.ly/1jwhtQ

http://adf.ly/1jwhtR

http://adf.ly/1jwhtS

http://adf.ly/1jwhtT

http://adf.ly/1jwhtU

http://adf.ly/1jwhtV

http://adf.ly/1jwhtW

http://adf.ly/1jwhtX

http://adf.ly/1jwhtY

http://adf.ly/1jwhtZ

http://adf.ly/1jwhta

EPLAN P8 PRO PANEL 2.6

EPLAN P8 PRO PANEL 2.6Eplan Electric P8 2.4 Crack

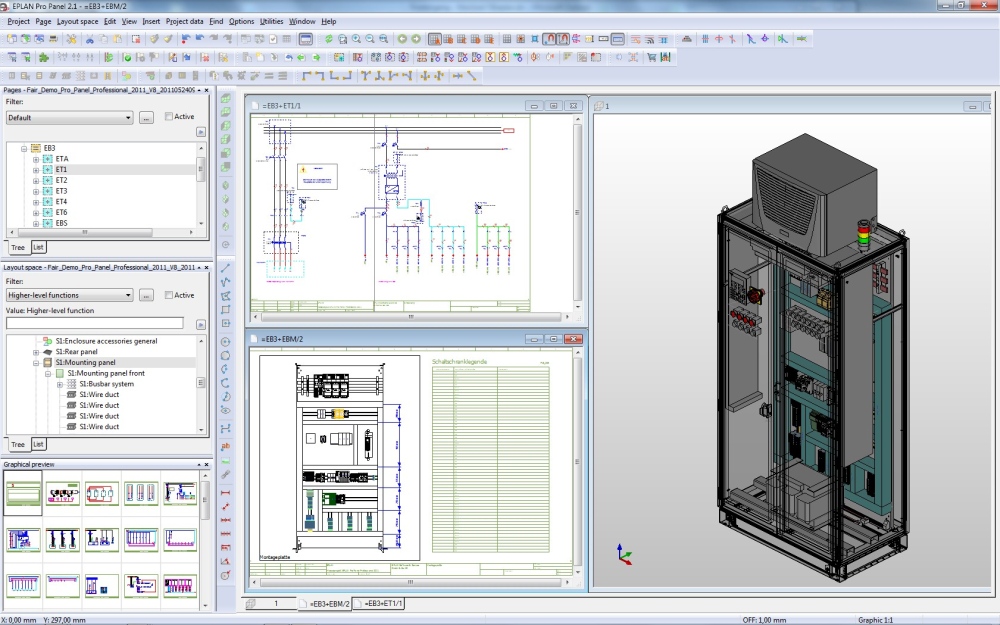

EPLAN Pro Panel Professional: Virtual enclosure layout in 3D

EPLAN Pro Panel Professional convinces through its deep degree of integration in the EPLAN platform and utilizes its manifold basic techniques such as the EPLAN device concept, the macro and options technology, access to the EPLAN Data Portal, etc. The design approach is individual: Optionally on the basis of a schematic or directly as layout of the enclosure in 3D. The devices provided for the mounting layout are displayed well-structured in Navigators or lists. During placing the system checks whether the positioning is carried out on the correct mounting panel.

The innovative eTouch technology allows components to be comfortably aligned and positioned exactly. Installation regulations and minimum spacing to manufacturer specification are taken into account as are the correct positioning of devices, wire ducts and mounting rails, including collision checks. The overview of all the designed devices and components allows the items to be checked simply on the basis of the parts data. Reports and bills of materials contain precise information also about items that vary in length such as wire ducts or mounting rails. Exact specifications therefore for manufacturing and mounting. Changes in the schematic or mounting layout are included in the entire project. The system informs interdisciplinarily and updates the associated drawings, bills of materials and legends automatically if desired. Thus ensuring uniform and consistent data that are always up to date.

Complete consistency

The software makes professional 3D layout planning easy even for the occasional user. Production relevant NC data for holes or cutouts is taken account in the 3D model and can be further processed. In addition to associative mounting diagrams special drilling templates for manufacturing can, for example, also be created. Modifications to housings, doors or mounting panels are transferred directly to the NC production systems via an NC interface. The deep manufacturing integration is also continued in the virtual wiring of the enclosure. The results of the length-optimized virtual wiring and cabling can in turn be used to optimize the schematic. The new quality in enclosure engineering covers all the phases of product development. The realistic 3D representation ensures high-quality data for manufacturing, mounting and operation. It facilitates the consistent creation, provision and maintenance of the documentation and accelerates the product engineering process persistently.

Manifold possibilities

EPLAN Pro Panel Professional provides manifold possibilities for the field of integrative enclosure planning, pre-assembly and production.

Added value at a glance

Benefit from numerous advantages for the virtual enclosure layout in 3D.

Modularization – the tailored fit for your system solution

Adapt EPLAN Pro Panel Professional perfectly to your workflows in engineering, technical preparations, manufacturing and mounting.

Product videos

Get an insight into EPLAN Pro Panel

System requirements

EPLAN Pro Panel Professional works with all standard Windows operating systems.

EPLAN Pro Panel Professional convinces through its deep degree of integration in the EPLAN platform and utilizes its manifold basic techniques such as the EPLAN device concept, the macro and options technology, access to the EPLAN Data Portal, etc. The design approach is individual: Optionally on the basis of a schematic or directly as layout of the enclosure in 3D. The devices provided for the mounting layout are displayed well-structured in Navigators or lists. During placing the system checks whether the positioning is carried out on the correct mounting panel.

The innovative eTouch technology allows components to be comfortably aligned and positioned exactly. Installation regulations and minimum spacing to manufacturer specification are taken into account as are the correct positioning of devices, wire ducts and mounting rails, including collision checks. The overview of all the designed devices and components allows the items to be checked simply on the basis of the parts data. Reports and bills of materials contain precise information also about items that vary in length such as wire ducts or mounting rails. Exact specifications therefore for manufacturing and mounting. Changes in the schematic or mounting layout are included in the entire project. The system informs interdisciplinarily and updates the associated drawings, bills of materials and legends automatically if desired. Thus ensuring uniform and consistent data that are always up to date.

Complete consistency

The software makes professional 3D layout planning easy even for the occasional user. Production relevant NC data for holes or cutouts is taken account in the 3D model and can be further processed. In addition to associative mounting diagrams special drilling templates for manufacturing can, for example, also be created. Modifications to housings, doors or mounting panels are transferred directly to the NC production systems via an NC interface. The deep manufacturing integration is also continued in the virtual wiring of the enclosure. The results of the length-optimized virtual wiring and cabling can in turn be used to optimize the schematic. The new quality in enclosure engineering covers all the phases of product development. The realistic 3D representation ensures high-quality data for manufacturing, mounting and operation. It facilitates the consistent creation, provision and maintenance of the documentation and accelerates the product engineering process persistently.

Manifold possibilities

EPLAN Pro Panel Professional provides manifold possibilities for the field of integrative enclosure planning, pre-assembly and production.

Added value at a glance

Benefit from numerous advantages for the virtual enclosure layout in 3D.

Modularization – the tailored fit for your system solution

Adapt EPLAN Pro Panel Professional perfectly to your workflows in engineering, technical preparations, manufacturing and mounting.

Product videos

Get an insight into EPLAN Pro Panel

System requirements

EPLAN Pro Panel Professional works with all standard Windows operating systems.

Show

EPLAN_Pro_Panel_2.6.part01.rar

EPLAN_Pro_Panel_2.6.part02.rar

EPLAN_Pro_Panel_2.6.part03.rar

EPLAN_Pro_Panel_2.6.part04.rar

EPLAN_Pro_Panel_2.6.part05.rar

EPLAN_Pro_Panel_2.6.part06.rar

EPLAN_Pro_Panel_2.6.part07.rar

EPLAN_Pro_Panel_2.6.part08.rar

EPLAN_Pro_Panel_2.6.part09.rar

EPLAN_Pro_Panel_2.6.part10.rar

EPLAN_Pro_Panel_2.6.part11.rar

EPLAN_Pro_Panel_2.6.part12.rar

EPLAN_Pro_Panel_2.6.part13.rar

EPLAN_Pro_Panel_2.6.part14.rar

EPLAN P8 PPE 2.6EPLAN_Pro_Panel_2.6.part02.rar

EPLAN_Pro_Panel_2.6.part03.rar

EPLAN_Pro_Panel_2.6.part04.rar

EPLAN_Pro_Panel_2.6.part05.rar

EPLAN_Pro_Panel_2.6.part06.rar

EPLAN_Pro_Panel_2.6.part07.rar

EPLAN_Pro_Panel_2.6.part08.rar

EPLAN_Pro_Panel_2.6.part09.rar

EPLAN_Pro_Panel_2.6.part10.rar

EPLAN_Pro_Panel_2.6.part11.rar

EPLAN_Pro_Panel_2.6.part12.rar

EPLAN_Pro_Panel_2.6.part13.rar

EPLAN_Pro_Panel_2.6.part14.rar

EPLAN PPE is the optimal tool for successful international collaboration in the planning and realization of electrical, measuring, and control system projects. Besides the maximum data and service compatibility, also the wide range of powerful interfaces, utilizing the full capacity of modern communication channels, supports collaboration by the whole project team over all the planning stages. This mobility and flexibility is particularly effective in the internal environment. For example, EPLAN PPE can also simplify and automatically advance adaptation and modernization processes at your own company. The new EPLAN technology provides a platform where fluid, electrical, measuring, and control engineering caninteract directly in interdisciplinary collaboration.

The overall concept behind EPLAN PPE is aligned to the present demands of measuring, control, and automation technologies. If work is to conform to the standards, a process control group concept based on NAMUR recommendations must be integrated. These NAMUR specifications for process control engineering are fully supported by EPLAN PPE. Its practical orientation and ease of use make EPLAN PPE an efficient tool for modern process plant engineering. Established methods and innovative developments have been combined into an extremely powerful and efficient solution.

The new modular Engineering platform technology is your key to the future, providing core functions for fluid, electrical, measuring, and control engineering as well as CAE for electrical systems. Based on a unified platform all systems are supplied from the same database. From now on multiple data entries and inconsistencies are history.

Besides a unified database the platform also includes basic functions like the graphical editor (for circuit diagrams, fluid plans, process control group plans), a unified rights management, the viewer, online/offline foreign language translations, and the comprehensive audit system. The unique framework concept delivers impressively fast results – not least of all owing to the unified look & feel throughout all applications.

The overall concept behind EPLAN PPE is aligned to the present demands of measuring, control, and automation technologies. If work is to conform to the standards, a process control group concept based on NAMUR recommendations must be integrated. These NAMUR specifications for process control engineering are fully supported by EPLAN PPE. Its practical orientation and ease of use make EPLAN PPE an efficient tool for modern process plant engineering. Established methods and innovative developments have been combined into an extremely powerful and efficient solution.

The new modular Engineering platform technology is your key to the future, providing core functions for fluid, electrical, measuring, and control engineering as well as CAE for electrical systems. Based on a unified platform all systems are supplied from the same database. From now on multiple data entries and inconsistencies are history.

Besides a unified database the platform also includes basic functions like the graphical editor (for circuit diagrams, fluid plans, process control group plans), a unified rights management, the viewer, online/offline foreign language translations, and the comprehensive audit system. The unique framework concept delivers impressively fast results – not least of all owing to the unified look & feel throughout all applications.

Show

EPLAN_PPE_2.6.part01.rar

EPLAN_PPE_2.6.part02.rar

EPLAN_PPE_2.6.part03.rar

EPLAN_PPE_2.6.part04.rar

EPLAN_PPE_2.6.part05.rar

EPLAN_PPE_2.6.part06.rar

EPLAN_PPE_2.6.part07.rar

EPLAN_PPE_2.6.part08.rar

EPLAN_PPE_2.6.part09.rar

EPLAN_PPE_2.6.part10.rar

EPLAN_PPE_2.6.part11.rar

EPLAN_PPE_2.6.part12.rar

EPLAN_PPE_2.6.part02.rar

EPLAN_PPE_2.6.part03.rar

EPLAN_PPE_2.6.part04.rar

EPLAN_PPE_2.6.part05.rar

EPLAN_PPE_2.6.part06.rar

EPLAN_PPE_2.6.part07.rar

EPLAN_PPE_2.6.part08.rar

EPLAN_PPE_2.6.part09.rar

EPLAN_PPE_2.6.part10.rar

EPLAN_PPE_2.6.part11.rar

EPLAN_PPE_2.6.part12.rar

EPLAN_PPE_2.6.part01.rar

EPLAN_PPE_2.6.part02.rar

EPLAN_PPE_2.6.part03.rar

EPLAN_PPE_2.6.part04.rar

EPLAN_PPE_2.6.part05.rar

EPLAN_PPE_2.6.part06.rar

EPLAN_PPE_2.6.part07.rar

EPLAN_PPE_2.6.part08.rar

EPLAN_PPE_2.6.part09.rar

EPLAN_PPE_2.6.part10.rar

EPLAN_PPE_2.6.part11.rar

EPLAN_PPE_2.6.part12.rar

EPLAN P8 EEC One 2.6EPLAN_PPE_2.6.part02.rar

EPLAN_PPE_2.6.part03.rar

EPLAN_PPE_2.6.part04.rar

EPLAN_PPE_2.6.part05.rar

EPLAN_PPE_2.6.part06.rar

EPLAN_PPE_2.6.part07.rar

EPLAN_PPE_2.6.part08.rar

EPLAN_PPE_2.6.part09.rar

EPLAN_PPE_2.6.part10.rar

EPLAN_PPE_2.6.part11.rar

EPLAN_PPE_2.6.part12.rar

Show

The use of EPLAN Engineering Configuration One (EEC One) is the first step on the road towards automation. In electrical and fluid engineering pre-defined standards such as circuit board elements or value sets are automatically collated into a wiring diagram based on Excel, thus simplifying machine design. In control cabinet and switchgear engineering, in EEC One combined with EPLAN Pro Panel, predefined 3D assembly layouts and more flexible control systems have reduced the time needed for the virtual configuration and assembly of mounting levels in control cabinets. Customers striving to standardise processes and data in engineering will benefit from this automation over the long term.

EPLAN_EEC_2.6.part01.rar

EPLAN_EEC_2.6.part02.rar

EPLAN_EEC_2.6.part03.rar

EPLAN_EEC_2.6.part04.rar

EPLAN_EEC_2.6.part05.rar

EPLAN_EEC_2.6.part06.rar

EPLAN_EEC_2.6.part07.rar

EPLAN_EEC_2.6.part02.rar

EPLAN_EEC_2.6.part03.rar

EPLAN_EEC_2.6.part04.rar

EPLAN_EEC_2.6.part05.rar

EPLAN_EEC_2.6.part06.rar

EPLAN_EEC_2.6.part07.rar